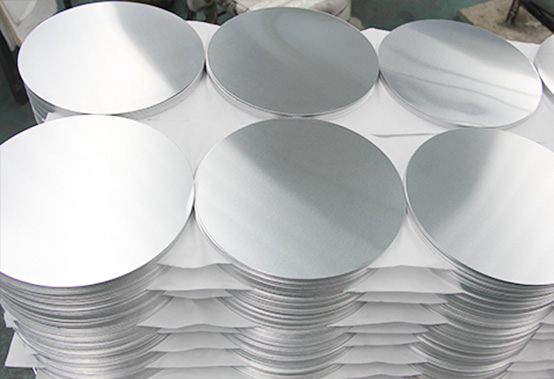

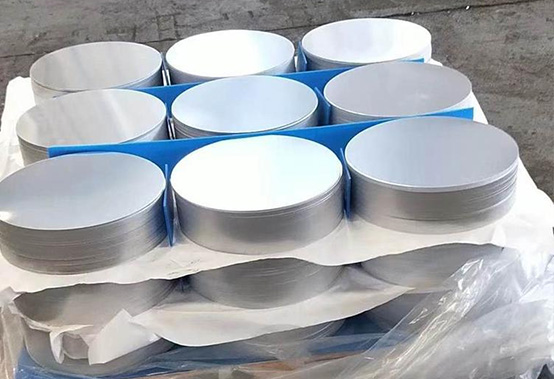

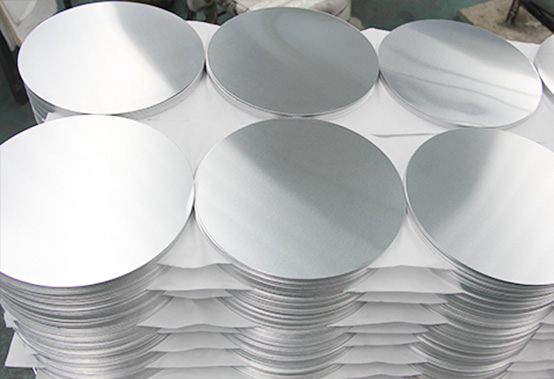

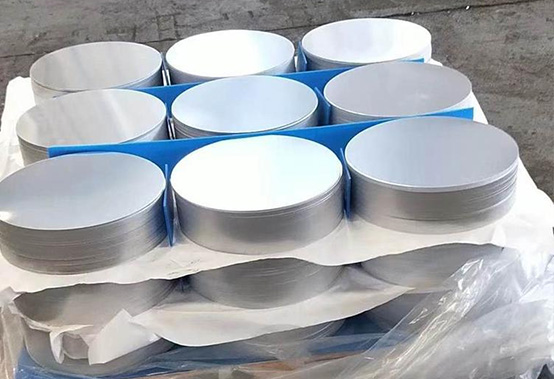

Aluminum Discs: Through rigorous control and testing of alloy, condition, and performance of the coil material in the early stage, we ensure the accuracy and diversity of the provided discs. This guarantees excellent deep drawing and spinning performance of the discs and effectively prevents potential defects like drawing lines, lotus leaf edges, and high ear-making rates during later processing. Our company offers both cold-rolled and hot-rolled aluminum discs, covering alloys from the 1, 3, 5, to 8 series.

|

ALLOY |

TEMPER |

GAUGE |

DIAMETER |

|

1050/1060/1100/1070/3003/3004/3005/3105/5052/5083/5754/8128 |

O、H*2、H*4、H*6、H*8、H111、H112 |

0.2-10mm 0.0079”-0.3937“ |

50-1550mm 1.9685”61.024“ |

1050 aluminum sheet & plate has the characteristics of high plasticity, corrosion resistance, good electrical and thermal conductivity, but it has lower strength.

1050 aluminum foil has low density, good electrical and thermal conductivity, and good corrosion resistance.

3003 aluminum foil is a commonly used product of the AL-Mn series of alloys.

1235 aluminum foil contains no less than 99.35% of aluminum. It can be processed into foil with a thickness ranging from 0.016mm to 0.2mm.

Mirror finish color coated aluminum coils are created through processes like rolling and polishing, giving the sheet a mirror-like effect.