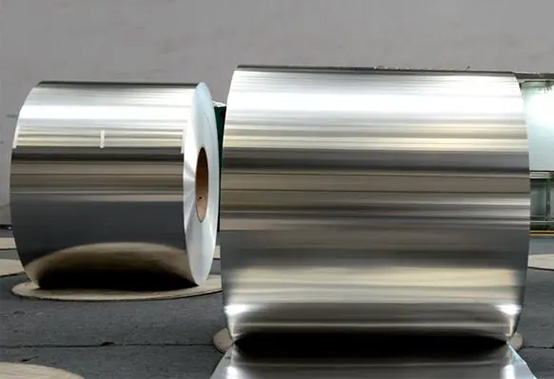

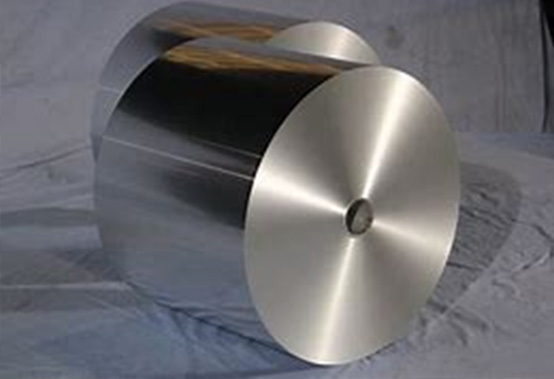

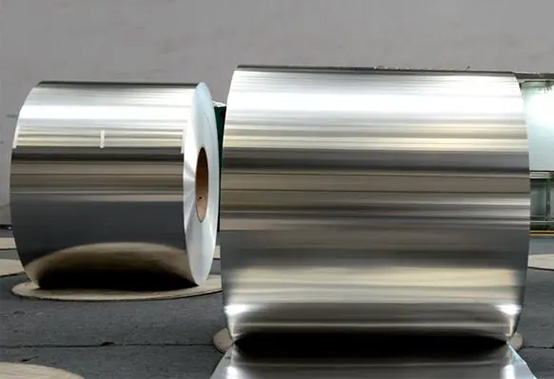

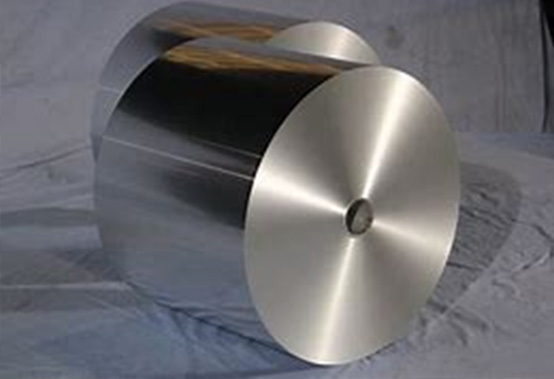

3003 aluminum foil is a commonly used product of the AL-Mn series of alloys. This product has excellent anti-rust characteristics, with a strength about 10% higher than 1100. It exhibits good formability, solubility, and corrosion resistance. It is used for processing parts that require good formability, high corrosion resistance and good weldability. 3003 aluminum foil is primarily used in electronic components (electronic foil), honeycomb materials, sound insulation in construction materials (viaduct, high-speed rail road sound barriers, etc.) and aluminum foils for food packaging (3003 aluminum foil bags, vacuum aluminum foil bags) and other industries.

13003 aluminum foil can be applied to electronic components (electronic foils), honeycomb materials, sound insulation in construction materials (such as viaducts and high-speed railway sound barriers), etc.

23003 aluminum foil can be used in food packaging foil (3003 aluminum foil bags, vacuum aluminum foil bags) and other industries.

|

ALLOY |

TEMPER |

GAUGE |

WIDTH |

LENGTH |

|

3003 |

O,H14,H16,H18,H19,H22,H24 |

0.01-0.2mm 0.0004”-0.0079“ |

100-1600mm 3.937”-62.992“ |

C |

3004 aluminum foil finds applications in various aspects, including food packaging and container foils for meal boxes.

Imitation wood grain color-coated aluminum sheets and coils come in a variety of colors and patterns, featuring excellent wood grain texture and a fresh natural beauty.

The raw material of color coated aluminum strip coil is pure aluminum or aluminum alloy, which is rolled into thin aluminum coil of different thickness and width by cold rolling machine.

Mirror finish color coated aluminum coils are created through processes like rolling and polishing, giving the sheet a mirror-like effect.

Brushed aluminum sheet is a process where brushed aluminum is used as a coating in PE paint, resulting in various brushed texture colors on the surface.