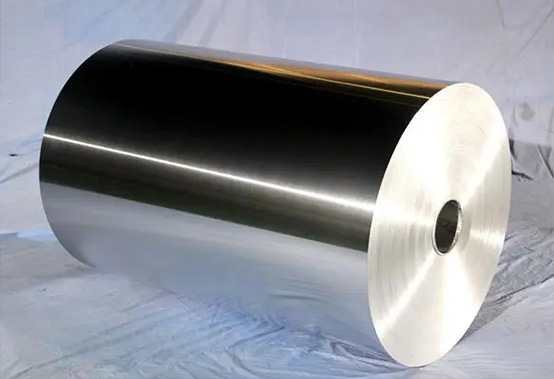

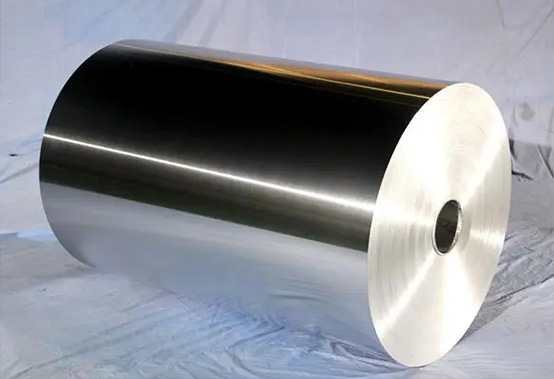

1050 aluminum foil has low density, good electrical and thermal conductivity, and good corrosion resistance.1050 aluminum foil usually refers to aluminum foil with aluminum content of 99.5%. Because it doesn’t require the addition of other chemical elements, the production process of 1050 aluminum foil is simple, and its price is relatively cheaper compared to alloy aluminum sheets. It is a widely used type of aluminum foil.

11050 aluminum foil can be used in food packaging, capacitors, cable belts, aluminum foil gaskets, etc.

|

ALLOY |

TEMPER |

GAUGE |

WIDTH |

LENGTH |

|

1050 |

O,H14,H16,H18,H19,H22,H24 |

0.01-0.2mm 0.0004”-0.0079“ |

100-1600mm 3.937”-62.992” |

C |

Due to its high plasticity, corrosion resistance, electrical conductivity and thermal conductivity

3004 aluminum foil finds applications in various aspects, including food packaging and container foils for meal boxes.

1070 aluminum foil has high plasticity, corrosion resistance, good electrical and thermal conductivity, making it suitable for aluminum foil gaskets and capacitors.

Solid color-coated aluminum sheets and coils are mainly divided into two types: polyester coating (PE) and fluorocarbon coating (PVDF).

The faux stone pattern coated aluminum sheet is a printed product created by roller-coating with fluorocarbon after the aluminum sheet undergoes pretreatment such as chromization.