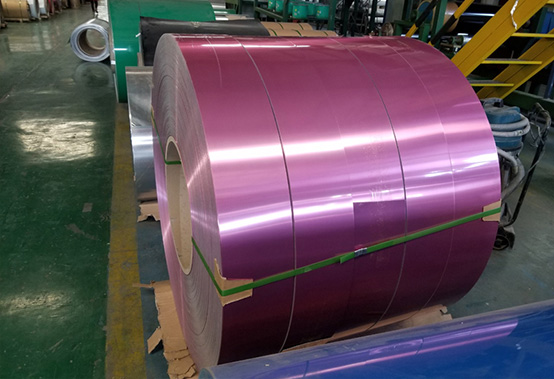

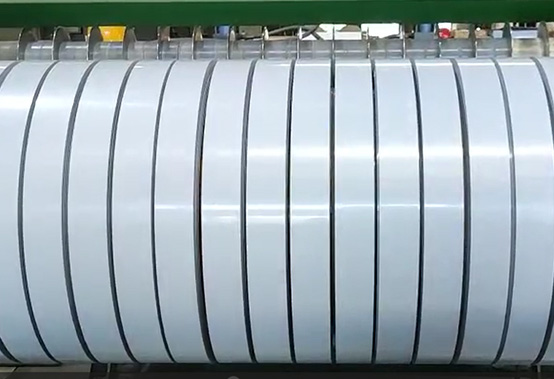

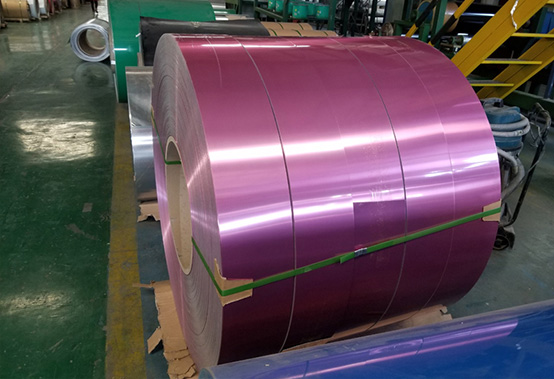

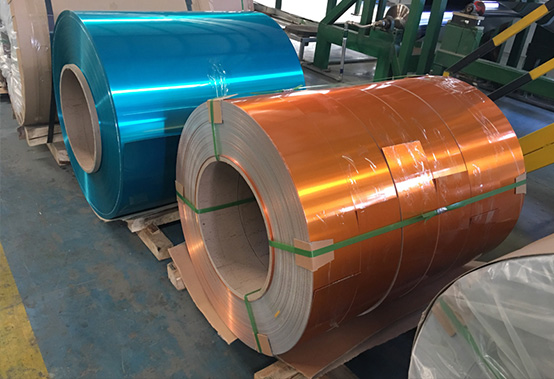

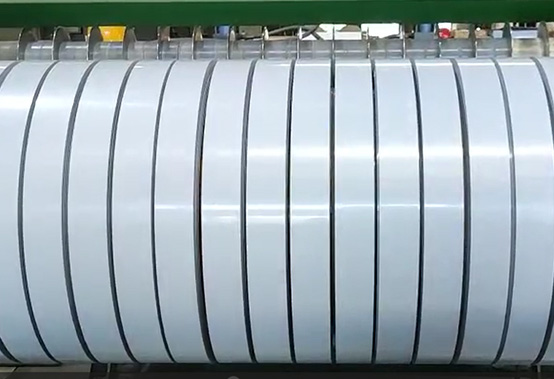

The raw material of color coated aluminum strip coil is pure aluminum or aluminum alloy, which is rolled into thin aluminum coil of different thickness and width by cold rolling machine. According to its purposes, a longitudinal slitter divides the strip into aluminum strips of different widths.

1Color coated aluminum strip coil can be used in transformer aluminum strip (transformer aluminum foil), insulating glass aluminum strips, radiator aluminum strips, cable aluminum strips, stamping aluminum strips, etc.

|

ALLOY |

TEMPER |

COATING GAUGE |

GAUGE |

WIDTH |

LENGTH |

|

1050、1060、1070、1100、3003、3004、3105、5005、5052、5754、8011 |

O,H12,H14,H16,H18,H22,H24, H26 |

As per customer’s requests |

0.2-4mm 0.0079“-0.1575” |

10-200mm 0.3937“-7.874” |

C |

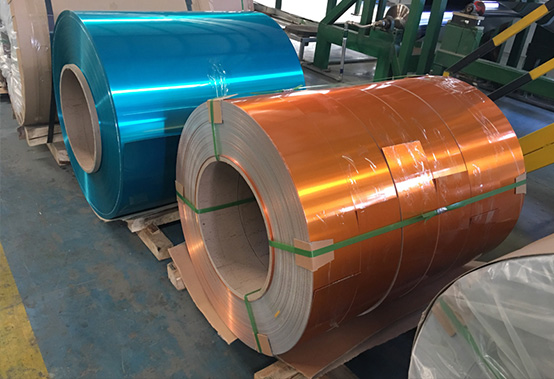

Solid color-coated aluminum sheets and coils are mainly divided into two types: polyester coating (PE) and fluorocarbon coating (PVDF).

The faux stone pattern coated aluminum sheet is a printed product created by roller-coating with fluorocarbon after the aluminum sheet undergoes pretreatment such as chromization.

Mirror finish color coated aluminum coils are created through processes like rolling and polishing, giving the sheet a mirror-like effect.

Aluminum strip coils are made from pure aluminum or aluminum alloys, which are processed through a cold rolling mill to produce thin aluminum coils of different thicknesses and widths.

Brushed aluminum sheet is a process where brushed aluminum is used as a coating in PE paint, resulting in various brushed texture colors on the surface.