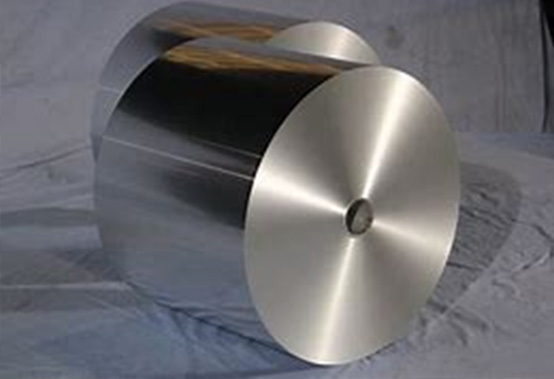

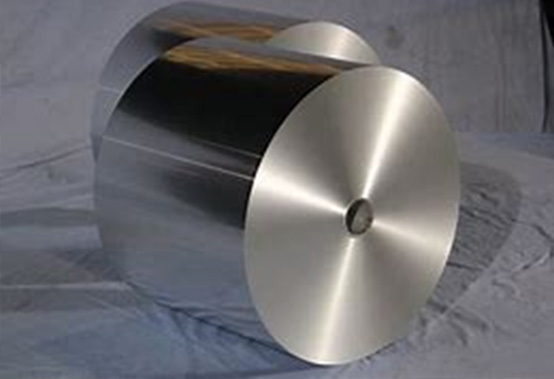

3004 aluminum foil finds applications in various aspects, including food packaging and container foils for meal boxes. It possesses high hardness and good load-bearing capacity. Its stamping performance is superior to that of 3003 aluminum foil, making it suitable for aluminum foil meal boxes, ensuring product hygiene. The product made from 3004 foil boasts multiple advantages: it has a good plate shape, is free from black spots, bright lines, and holes, and offers a combination of high quality and affordability.

13004 aluminum foil can be used for mealbox materials, container foils, bottle cap materials, food packaging and other industries.

|

ALLOY |

TEMPER |

GAUGE |

WIDTH |

LENGTH |

|

3004 |

F,O,H14,H16,H18,H19,H22,H24,H26,H28 |

0.02-0.2mm 0.0008”-0.0079“ |

100-1600mm 3.937”-62.992” |

C |

The raw material of color coated aluminum strip coil is pure aluminum or aluminum alloy, which is rolled into thin aluminum coil of different thickness and width by cold rolling machine.

Solid color-coated aluminum sheets and coils are mainly divided into two types: polyester coating (PE) and fluorocarbon coating (PVDF).

Mirror finish color coated aluminum coils are created through processes like rolling and polishing, giving the sheet a mirror-like effect.

Brushed aluminum sheet is a process where brushed aluminum is used as a coating in PE paint, resulting in various brushed texture colors on the surface.

Imitation wood grain color-coated aluminum sheets and coils come in a variety of colors and patterns, featuring excellent wood grain texture and a fresh natural beauty.